- Description

- Technical Data

- Equipment: Base / Base addition

- Equipment: Reservoir

- Equipment: Drive

- Equipment: Feed tube

- Equipment: Nozzles

- Equipment: Options

Piston pump system for spraying the smallest quantities of liquid.

Main application range:

External MQL for circular saws and band saws.

Operating principle:

The liquid flows from the reservoir into a piston pump. This pushes an exact quantity of the lubricant into the internal feed tube. Separately supplied compressed air splits the medium in the nozzleblock into tiny particles of fluid and sprays it onto the tooth profile of the saw.

Adjustability

-

Swept volume of the pump (manual)

-

Clock frequency of the pump (manual)

-

Quantity of spray air (manual)

-

Switch on/off using actuation control drive (electric, pneumatic or manual)

| Term | Figure | Unit |

|---|---|---|

| Operating pressure | 4 - 8 | bar |

| Liquid flowrate | 0-150* | ml/h per nozzle |

| Typical consumption | 15-30* | ml/h per nozzle |

| Lubricoolant | Lubrimax® and others | |

| Recommended viscosity | 1 - 50* | mm²/s (at40°C) |

| Dimensions | HxWxD (mm) | |

|---|---|---|

| Housing (without reservoir) | 200x200x155 | |

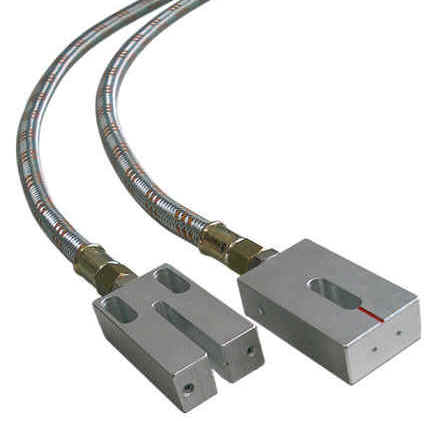

| Nozzleblock | 15x52x30 |

(from 0.33 to 3 litres available):

Housing Assembly

(electric, pneumatic, manual or mechanic option)

– Solenoid valve 3/2 way (120 Nl/min) with auxiliary actuation (for occasional manual switching on/off). Coil with plug in 24V DC, 24V AC, 110V AC or 230V AC. Cable bushing on left side of housing.

– Pneumatic valve 3/2 way (550 Nl/min). With push in connection ø4 for control air on left outer side of housing.

– Hand valve 3/2 way (600 Nl/min) as valve rocker on right outer side of housing.

– Mechanical valves 3/2 way (700Nl/min) as plunger, roller lever or knee roller lever in versions NC or NO. Delivered with the corresponding connectors and a 2m tube PUNØ8 to the unit.

– Coaxial feed tube with EASY-COAX® system. Outer tube of strong rubber construction with robust metal sleeve Ø11, inner tube for delivery of medium, constructed of long-life PTFE Ø3. Smallest bending radius 50 mm. Standard length 3,000, non-standard lengths up to 20,000 available on request.

– 4 x round magnet Ø80 (mounted on the reverse side) for easy installation of the housing.

– 4 x mounting straps (mounted on the reverse side) for fixed installation of the housing.