- Description

- Technical Data

- Equipment: Base/Base addition

- Equipment: Reservoir

- Equipment: Drive

- Equipment: Feed tube

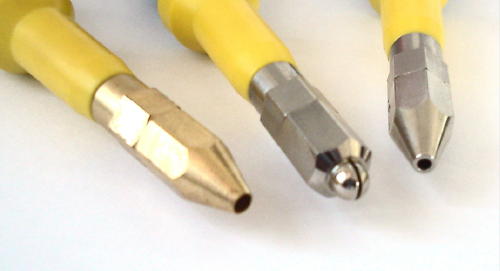

- Equipment: Nozzles

- Equipment: Options

Low pressure system for spraying runny substances in medium quantities.

Introduction:

Spraymat S700 is the Venturi spray system, replacing the successful Spraymat S100 and S600 series by combining the advantages of both systems into one. Due to the modular design of the new valve block a synchronous or, if required, a separate drive of the nozzles can be realized. The new reservoirs available with 1, 6, 20 and 40 litre volume can be mounted by means of wall brackets or placed at the ground. The Venturi nozzles have been completely redesigned and are available in two sizes: VD07 (with a capacity of up to 1l/h) and VD15 (up to 6l/h). So you can easily adopt the performance of your Spraymat S700 to your requirements just by changing the nozzle. In addition the nozzle tip can be replaced in case of damage. And for the VD07 size nozzle, the nozzle tip is available as a standard full jet or a flat-jet. pump system for spraying the smallest quantities of liquid.

Main application range:

External MQL in simple metal-cutting operations. Application of substances in not too small quantities. Depending on the substance and type of application, a suction is recommended

Operating principle:

In the Venturi nozzle , the spray air produces a partial vacuum, which causes the liquid to be sucked out of the unpressurized reservoir and sprayed.

Adjustability

-

Spray air quantity (manual)

-

Quantity of liquid (manual)

-

Spray air pressure (manual)

-

Switch on/off using actuation control drive (electric, pneumatic or manual)

| Term | Nozzle VD07 | Nozzle VD015 | Unit |

|---|---|---|---|

| Operating pressure | 4 - 7 | 4 - 7 | bar |

| Liquid flowrate | 0 - 1.000* | 0 - 6.000* | ml/h per nozzle |

| Typical consumption | 30 - 50* | 50 - 100* | ml/h per nozzle |

| Lubricoolant | Lubrimax® and others | Lubrimax® and others | |

| Recommended viscosity | 1 - 50* | 1 - 100* | mm²/s (at 20°C) |

| Max. suction height | 1.000* | 3.000* | mm |

| Max. feed tube length | 10.000* | 20.000* | mm |

| Dimensions ** | with reservoir - HxWxD in mm |

|---|---|

| S700/1-Y1W | 1 litre - 250 x 175 x 150 |

| S700/1-Y6W | 6 litres - 250 x 300 x 200 |

| S700/1-Y20 | 20 litres - 300 x 400 x 300 |

| S700/1-Y40 | 40 litres - 300 x 600 x 400 |

* depending on application, medium, temperature, viscosity

** Size depends on number of nozzles and type of drive (synchronous or separate)

– Needle valve for each nozzle to adjust air spray.

– Needle valve for each nozzle to adjust quantity of liquid.

– Ascending pipe for liquid with non-return valve and liquid filter.

– Pressure reducing valve for spray air to adjust spray jet (low pressure = coarse spray droplets; high pressure = fine spray droplets).

– Manometer (0 – 10 bar) on pressure reducing valve to indicate spray air pressure.

– Push-in connection for compressed air supply Ø6.

(electric, pneumatic or manual option:)

– Solenoid valve 3/2 way (up to 4 nozzles 120 Nl/min, over 4 nozzles 1300 NL/min) with auxiliary actuation (for occasional manual switching on/off). Coil with plug in 24VDC, 24VAC, 110VAC or 230VAC. In case of separate actuation each nozzle (group) controlled via a dedicated solenoid valve.

– Pneumatic valve 3/2 way (up to 4 nozzles 550 Nl/min, over 1300 NL/min)

– Hand actuated ball valve (2/2 way).

– Coaxial feed tubes, PUN Ø8 outer with internal PUN Ø3. Standard length: 1,000; non-standard length: see Technical Data. On request with outer metal protection sleeve.

Pneumatic drip shut-off system (per nozzle) in FPM. Required if the nozzle is inserted underneath (otherwise danger of subsequent dripping) or far above (otherwise increased reaction time) of the reservoir level.